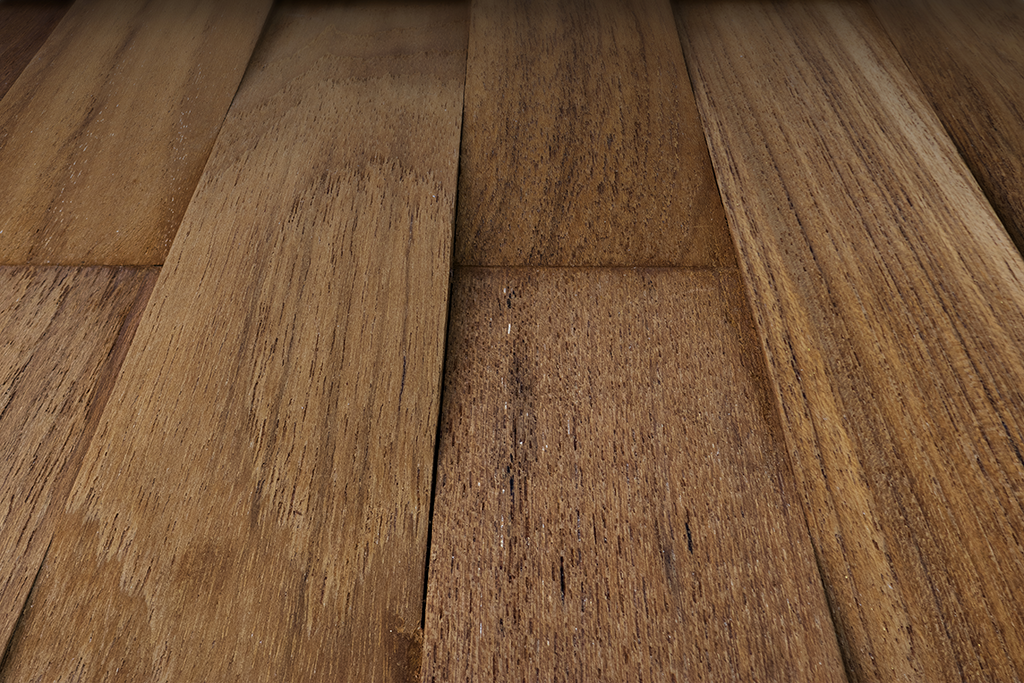

Even after being turned into flooring, wood remains a natural substance that responds to changes in its surroundings. It’s true that producers have created various hardwood floor structures in an effort to “improve and control” the way wood reacts to variations in humidity. However, maintaining a healthy home atmosphere and the attractive appearance of your hardwood floor still depend on maintaining humidity at the suggested level.

High humidity is one of the most prevalent causes of wood rot, as most of us are aware. Moisture in the air can cause wood fibers to expand and become less stiff. Wooden floors that are exposed to too much moisture may decay, harming your foundation and walls.

Low humidity levels, however, can also be detrimental. In very dry regions, wood can shrink and become brittle. Sustaining optimal humidity and temperature levels is crucial for maintaining the optimal condition of your floor.

Regulate Moisture and Temperature for Hardwood Floors

The ideal humidity and temperature ranges depend on the kind of wood your flooring is made of.

Nonetheless, at normal room temperature (65 degrees F), hardwood floors should be between 35% and 45% humidified. It can naturally require a few more efforts to keep a constant interior atmosphere, depending on where you reside.

When doing pre-installation processes, an important thing to do is monitor the temperature and humidity, wherever feasible. By doing this, you may more easily understand what preserving your floors entails and what “equilibrium” means for you.

Before work testing, the building envelope (walls, roofing, windows, entrances, etc.) must be sealed and weathertight. Floor covering installation cannot commence until all other trades have been finished. Before installation, the building’s HVAC system must be operational and permanent. A minimum temperature of 68°F (20°C) must be maintained for at least 72 hours before, during, and following the event. The installation location and materials must be kept at temperatures between 68°F and 85°F during the installation process.

You should also know that excessive relative humidity levels must be avoided. All materials and subfloors must be completely acclimated to the installation temperature. The installation areas must be well-lit so that the flooring and subfloor may be properly inspected. This is especially important for flash coving. The installation area must be at least 5 degrees from the dew point. During adhesive application, low relative humidity (dry air) is required and must be maintained. Installations shall not take place when the substrate of the installation area is less than 5 degrees above the dew point.

Moisture testing

Moisture testing is crucial for assessing a concrete slab’s viability for resilient flooring applications. Also, it is required for all concrete slabs, regardless of age or grade level. This includes sections with resilient flooring.

Moisture testing should take place under service circumstances, which include a completely enclosed, weather-tight structure with permanent HVAC. Test findings only reflect present moisture conditions and cannot forecast future circumstances.

When you bring hardwood flooring materials to the job site, use a moisture meter to scan them, checking 40 boards for every 1,000 square feet of flooring. Any boards with unusually high or low moisture readings should be set aside and not installed.

Generally, moisture readings should be between 6 and 9 percent, but you should aim for the expected Equilibrium Moisture Content (EMC). If the boards aren’t at the EMC, the NWFA recommends “cross-stacking the materials with spacers (¾-inch to 1-inch stickers) between each layer of flooring to allow air circulation on all sides.”

Continue testing the boards until they reach the EMC and match the subfloor’s moisture content levels.

A pinless meter allows you to scan a large number of boards while swiftly avoiding pinholes. When utilizing pin meters, glue the boards to the rear to avoid damaging the material’s face. Make sure the meter is calibrated and set for the appropriate wood species.

Document Test Results

When testing the materials for moisture, make sure to document the date, time, and results. This manner, you can demonstrate to clients that you conducted your due diligence while avoiding being held accountable for problems you did not cause.