Today’s wood finishing realm presents a vast array of options for both woodworkers and hobbyists. From time-honored oil finishes to sophisticated varnishes, lacquers, and polyurethane coatings, an extensive selection of products is at hand to both beautify and protect wooden surfaces. Woodworkers can freely select the finish that aligns best with their project, taking into account aspects like durability, visual appeal, and environmental considerations.

Contemporary wood finishing techniques offer limitless opportunities to highlight the innate allure of wood while ensuring its preservation for the future. Whether one is drawn to the traditional charm of an oil finish that accentuates the wood’s natural colors and grain or the robust protection of a high-gloss polyurethane coating that resists wear and tear, there’s a suitable finish to fulfill every unique requirement.

Specialized finishes like varnishes and lacquers are a favorite among woodworkers, as they effectively safeguard wood surfaces from moisture, UV rays, and other environmental factors. Moreover, these finishes give wood a polished and sleek look, enhancing its overall appearance.

The modern wood finishing market offers finishes in different colors and sheens to cater to varying preferences. Whether you prefer a natural, matte finish or a glossy, vibrant look, there are options available to suit your aesthetic tastes.

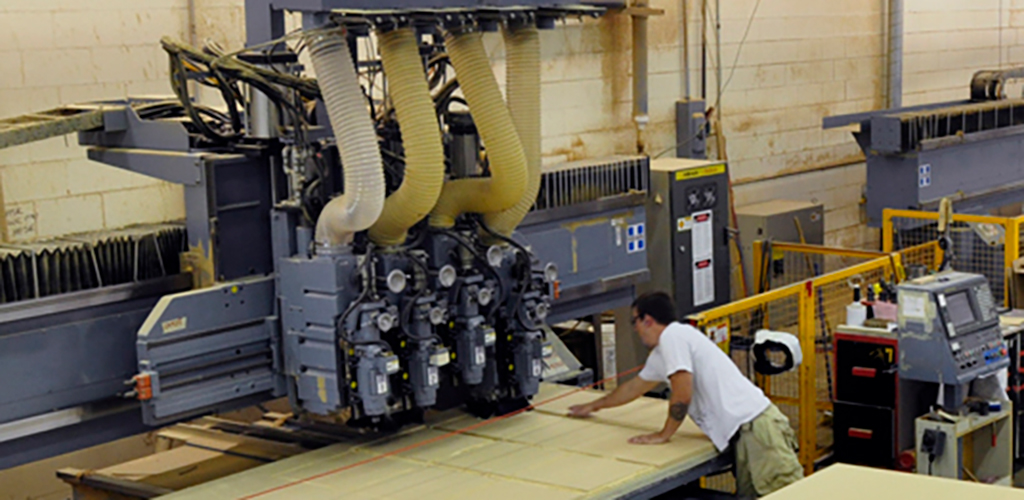

In addition to a wide range of finishes, modern technology has introduced innovative application methods and tools to woodworkers. These advancements have made it easier for beginners to achieve professional-level results, resulting in enhanced precision and efficiency in wood finishing equipment.

Technological Integration in Wood Finishing Equipment

The way wood finishing processes are carried out has been transformed by technological advancements. One such innovation is the implementation of Programmable Logic Controller (PLC) software, which allows for precise adjustments and automation of the finishing process. This software permits operators to program specific parameters and sequences. So the PLC reduces the risk of human error and ensures the consistent application of finishes.

Enhanced machine control systems also play a critical role in the accuracy and reliability of wood-finishing equipment. By regulating temperature, pressure, and speed, operators can achieve optimal results with minimal manual intervention. These improvements in machine control have significantly enhanced the overall quality and consistency of wood finishes.

In addition to machine control, sensor technology is also essential in wood-finishing equipment. Sensors are utilized to provide accurate readouts and feedback on various parameters during the finishing process, ensuring consistency and precision. Moisture sensors, for instance, can detect and measure the moisture content of wood surfaces. This allows operators to make informed decisions regarding the application of finishes. This guarantees that the finishes adhere correctly and result in the desired appearance and durability.

Through the use of sensor technology, wood finishing equipment can ensure that color values are analyzed and compared. So it results in uniformity and consistent color matching across various wood pieces. This enables the equipment to achieve the desired aesthetic outcomes with precision and reliability.

Environmental Advancements in Wood Finishing

The wood finishing industry has seen significant progress in environmental and safety practices in recent years. These developments prioritize sustainability and operator well-being, thus making the industry more accountable and productive.

Efficiency and sustainability have become essential aspects of wood-finishing machinery. Energy-saving features and sustainable practices are now commonplace, contributing to the conservation of resources and maintaining high-quality finishes.

Machinery manufacturers have also adopted sustainable practices. They use eco-friendly materials in equipment construction, reduce waste, and implement recycling initiatives. Such actions are crucial to preserving the environment for future generations.

Another area of focus is operator safety. Advanced systems have been developed to minimize the risks associated with the finishing process. For instance, dust collection systems are integrated into wood finishing machinery to improve operator safety.

The wood finishing industry has made significant strides in creating a safer working environment. To promote worker health and safety, fume exhausts have been implemented to effectively eliminate dangerous fumes and VOCs. This has greatly reduced the risk of respiratory issues and other health concerns for operators. Additionally, motion detection sensors are now used in wood finishing equipment to prevent accidents and injuries.